The transformer coil is an indispensable and important component in the power system, and its performance directly affects the efficiency and stability of the transformer. This article will provide a detailed analysis of the characteristics of transformer coils to help readers better understand this key component.

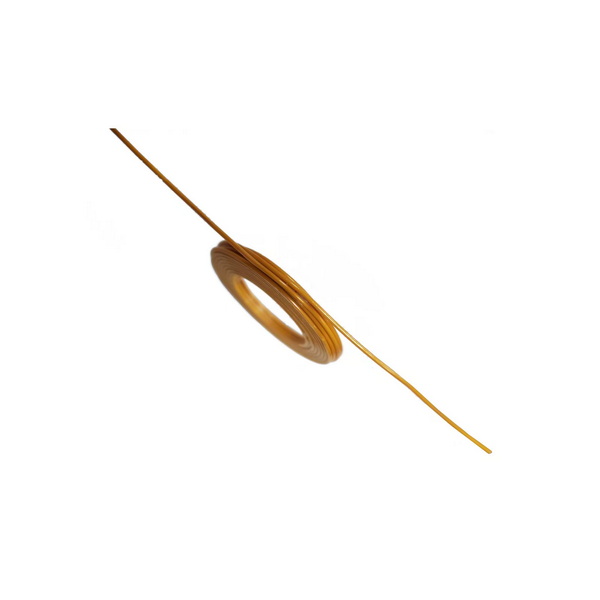

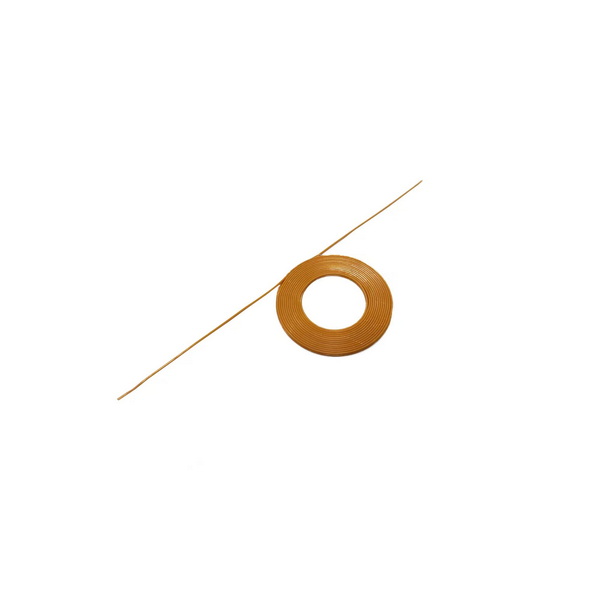

Basic structure of transformer coil

Transformer coils are mainly composed of conductors, insulation materials, and magnetic cores. Conductors are usually made of copper or aluminum, which have excellent conductivity and can effectively reduce energy loss. The insulation material ensures the safety of the coil when operating at high voltage, and commonly used insulation materials include paper insulation and polyester film. The structure of transformer coils affects their working efficiency and service life, so various factors need to be considered in the design.

Electrical characteristics of transformer coils

The electrical characteristics of transformer coils mainly include resistance, inductance, and capacity. Resistance is an important factor affecting coil heating, and low resistance coils can effectively reduce energy loss. Inductance is related to the number of turns and layout of the coil. The higher the inductance value, the stronger the voltage conversion ability of the transformer. In addition, the capacity of the transformer coil determines the power it can carry, and a reasonable design can improve the safety and stability of the equipment.

Thermal characteristics of transformer coils

Thermal characteristics are important indicators for evaluating the performance of transformer coils. Transformers generate heat during operation, and excessively high temperatures may cause insulation material aging, coil damage, and even equipment failure. Therefore, the heat dissipation design of transformer coils is particularly important. An efficient heat dissipation system can keep the coil within a safe temperature range, improving the stability and lifespan of the transformer.

Material selection for transformer coils

The material selection of transformer coils directly affects their performance and cost. Copper coils are widely used due to their excellent conductivity and low resistance. Although they are expensive, they perform better in high-performance applications. Although aluminum coils have slightly inferior conductivity, they have lower costs and are suitable for cost sensitive applications. Choosing appropriate materials can achieve a good balance between performance and economy.

Production process of transformer coils

The production process of transformer coils is equally critical, usually including winding, insulation treatment, and testing steps. The winding process requires precise control of the number of turns and layout of the coil to ensure its electrical performance meets design requirements. Insulation treatment is a key step in ensuring the safe operation of transformer coils under high voltage, and high-quality insulation materials must be used for multiple treatments. In addition, post production testing is an important step in ensuring coil performance, as it can identify potential issues and reduce failure rates.

Application fields of transformer coils

Transformer coils are widely used in various fields such as power, communication, and transportation. In the power system, transformer coils are responsible for voltage conversion and energy transmission, ensuring efficient utilization of electrical energy while maintaining system stability. In the field of communication, transformer coils are used for signal processing to ensure the accuracy and reliability of data transmission. In the transportation system, transformer coils are used for power supply to support the normal operation of equipment such as electric trains.

In summary, the characteristics of transformer coils determine their importance in the power system. Through a comprehensive analysis of its structure, electrical characteristics, thermal characteristics, material selection, production process, and application fields, it can be seen that the rational design and selection of high-quality transformer coils are the key to ensuring the efficient and safe operation of the power system. In the future development, with the continuous advancement of technology, the performance of transformer coils will be further improved, providing more reliable power support for various industries.