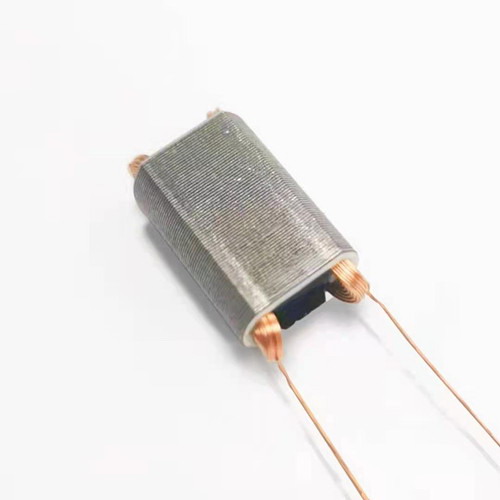

Bobbin Coil

The tolerance size of the inner and outer diameters of the skeleton coil is controlled at a minimum of 0.01mm, and the inductance tolerance can be controlled to ± 2.5%; Individual users who require high precision can produce products as small as 0.5-1mm medical industry sensors; In the selection of raw materials and wires for motor linear motor coils, well-known listed and foreign-funded enterprises in the industry are used to ensure the quality and stability of the products to the greatest extent possible. Moreover, strict testing must be carried out before the finished skeleton coils are released from the warehouse to ensure quality and safety.

Skeleton coils are generally composed of windings, skeletons, magnetic cores, shielding covers, etc. The supports of skeleton coils have different shapes and are made of materials such as glued laminated wood, ceramics, polystyrene, mica, etc; The main applications include textile machine sensor coils, monitor induction coils, charger skeleton coils, electric meter skeleton coils, camera skeleton coils, audio skeleton coils, smart toilet coils, point reading machine skeleton coils, lifting table and chair skeleton coils, beauty instrument coils, smart door lock skeleton coils, etc. It can be said that the coverage range is very wide, and with the rapid development of electronic products in the future, demand will continue to increase.

Application fields of motor linear motor coils: smart water and electricity meters, electronic tags, bicycles, frequency dividers, solenoid valves, security equipment, electronic cigarettes, coin operated devices, sensors, leakage protection switches, computer peripherals, textile machines, wireless mice, beauty devices, smart door locks, medical machinery, power supplies, learning machine point readers, mobile phones, household appliances, Bluetooth earphones, Internet of Things, electric toothbrushes, children's toys, etc.