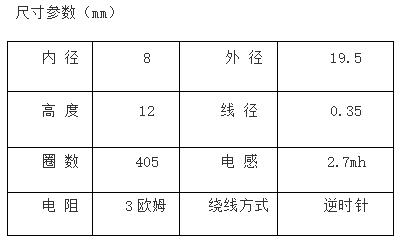

Magnetic levitation 90 inductor coil

Magnetic levitation 90 inductor coil is a customized model of magnetic levitation coil. This magnetic levitation inductor coil is mainly designed for products with small suspension force and volume, saving costs while maintaining performance. The coil manufacturer provides various customized magnetic levitation coil projects and can develop coils suitable for your product according to your requirements.

The winding methods of magnetic levitation inductance coils can be divided into single-layer coils and honeycomb winding methods, where insulated wires are wound one after another on paper tubes or rubberwood frames. Like the wave antenna coil in a transistor radio. A single-layer winding is a winding in which only one coil effective edge is embedded in each stator slot, so its total number of coils is only half of the total number of slots in the motor. The coil wound in a honeycomb style has a plane that is not parallel to the rotating surface, but intersects at a certain angle. The advantages of honeycomb winding method are small size, small distributed capacitance, and large inductance. Honeycomb coils are wound using a honeycomb winding machine, and the more bends there are, the smaller the distributed capacitance.

Magnetic levitation inductor coils have a small volume, low latent capacitance, high inductance, and high Q value. Therefore, many radio tuning coils, oscillation coils, and high-frequency chokes are wound in this way, and the effect is better than other methods. In factories, this type of coil is usually wound using a beehive car.